A Plastic Recycling Granulation Machine imhando yemidziyo inoshandiswa kugadzira marara kana kurasa epurasitiki kuita reusable plastic granules. Inonyungudutsa pasi zvinhu zvepurasitiki zvakashandiswa sePE, PP, kana PET uye inozvigadzirisa kuita madiki, yunifomu pellets kuburikidza neextrusion nekucheka.

Muchina uyu unoita basa rakakosha mukudzoreredza epurasitiki nekushandura mapurasitiki akaraswa kuita zvigadzirwa zvezvigadzirwa zvitsva. Inobatsira kudzikisira kusvibiswa kwepurasitiki, inodzikisa mitengo yekugadzira, uye inotsigira kugadzirwa kwakasimba mumaindasitiri ese sekurongedza, kuvaka, uye zvinhu zvevatengi.

Kunzwisisa maficha, zvakanakira nezvayakaipira, uye zvinobvira mashandisirwo ePlastiki Recycling Granulation Machine ichakubatsira iwe kuita sarudzo dziri nani uye kusarudza iyo chaiyo granulator kana musanganiswa kuti usangane nezvinodiwa zvekugadzira.

Verenga mberi apo isu tinodonongodza akati wandei akasiyana ePlastiki Recycling Granulation Machines uye ipa pfupiso pfupi pakupera kwechinyorwa kuti usarudze yakanakisa granulator yepurojekiti yako.

Mhando dzePlastic Recycling Granulation Machine

Yemazuvano Plastic Recycling Granulation Machines akagadzirwa ane simba-rinoshanda masisitimu, otomatiki tembiricha yekudzora, uye kusefa kwepamberi kuve nechokwadi chemhando yepamusoro granules. Iwo anoshandiswa zvakanyanya mukudzoreredza zvidyarwa, mafekitori ezvigadzirwa zvepurasitiki, uye nzvimbo dzekugadzirisa zvakatipoteredza kubata zvakasiyana-siyana zvemarara epurasitiki, kubva mufirimu nemabhodhoro kusvika kune majekiseni-akaumbwa zvikamu.

Tevere, tichakurukura muchidimbu marudzi gumi nemaviri akasiyana emagranulator.

1. Recycling compactor granulation line

A Recycling Compactor Granulation Line ndiyo yakakwana sisitimu inoshandiswa kugadzira marara epurasitiki akareruka — senge mafirimu, mabhegi akarukwa, uye zvinhu zvine furo — mumapepa epurasitiki akakora. Iyo inosanganisa compaction, extrusion, filtration, uye pelletizing kuita imwe inoenderera maitiro. Iyo compactor pre-compresses yakapfava kana yakakura zvinhu, zvichiita kuti zvive nyore kudyisa muextruder pasina bhiriji kana kuvhara.

Zvakanakira

Kudya Kunobudirira: Iyo yakavakirwa-mukati compactor pre-magadzirirwo akareruka uye fluffy zvinhu, kudzivirira kudyisa blockages.

Integrated System: Inosanganisa compaction, extrusion, filtration, uye pelletizing mumutsara mumwe unoenderera.

Space & Labor Kuchengetedza: Compact dhizaini ine yakakwira otomatiki inoderedza kudiwa kwebasa remanyorero uye nzvimbo yefekitori.

Wide Material Kuenderana: Inobata akasiyana mapurasitiki akapfava sePE / PP firimu, mabhegi akarukwa, uye furo zvinhu.

Consistent Pellet Hunhu: Inogadzira mayunifomu epurasitiki granules akakodzera kushandiswa zvakare mukugadzira.

Zvakaipa

Haikodzeri Mapurasitiki Akaoma: Mapurasitiki akakora kana akaomarara (semuenzaniso, majekiseni-akaumbwa zvikamu, mabhodhoro) anogona kuda mimwe michina.

Hutsanana Hunodiwa: Hunyoro hwepamusoro kana mazinga ekusvibiswa (setsvina kana bepa) anogona kukanganisa kuita uye kunaka kwepellet.

Kugara Kwekuchengetedza Kunodiwa: Iyo compactor uye filtration nzvimbo dzinoda kucheneswa nguva nenguva kuti ive nechokwadi chekushanda kwakagadzikana.

Applications

Zvekurima Firimu Kudzokorodza: YePE mulch firimu, greenhouse film, uye mamwe mapurasitiki emarara epurazi.

Post-Consumer Plastic Packaging: Yakanakira kugadzirisa mabhegi ekutenga, kutambanudza firimu, mabhegi ekutumira, nezvimwe.

Industrial Scrap Recovery: Inodzokorodza tsvina yekugadzira kubva mufirimu uye vakarukwa mabhegi vanogadzira.

Plastic Recycling Plants: Yakanyatsokodzera zvivakwa zvinobata mavhoriyamu makuru emarara epurasitiki akapfava.

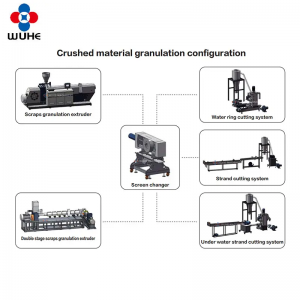

2.Yakapwanyika zvinhu granulation line

A Crushed Material Granulation Line ipurasitiki yekudzokorodza sisitimu yakagadzirirwa kugadzirisa tsvina yakaoma yepurasitiki iyo yakatocherwa kana kupwanyiwa kuita maflakes. Izvi zvinosanganisira zvinhu zvakaita seHDPE, PP, PET, ABS, kana PC kubva mumabhodhoro, midziyo, uye zvimedu zveindasitiri. Mutsara unowanzo sanganisira yekudyisa system, imwe chete kana mapatya-screw extruder, filtration unit, pelletizing system, uye kutonhora / kuomesa chikamu.

Zvakanakira

Kudya Kwakananga Kwezvinhu Zvakapwanyika: Hapana kudikanwa kwepre-compaction; akakodzera mapurasitiki akaoma semabhodhoro, midziyo, uye zvikamu zvejekiseni.

Yakagadzikana Kubuda: Inoshanda zvakanaka neunifomu, dense zvinhu, inopa inowirirana extrusion uye pellet mhando.

Kunyanya Kubudirira: Yakasimba screw dhizaini uye inoshanda degassing system inovandudza kunyungudika uye kuderedza hunyoro nyaya.

Flexible Configuration: Inogona kuve yakashongedzerwa ine imwe chete kana mapatya-nhanho extruders, mhete yemvura kana strand pelletizers zvichienderana nemhando yezvinhu.

Yakanakira Kuchenesa Regrind: Kunyanya inoshanda kana uchigadzira yakachena, yakarongedzwa maflakes epurasitiki kubva mumitsara yekuwachisa.

Zvakaipa

Haina Yakanakira Soft kana Fluffy Plastics: Zvinhu zvakareruka senge mafirimu kana furo zvinogona kukonzera kusagadzikana kwekudya kana bhiriji.

Inoda kugezwa kusati kwatanga: Yakasviba kana yakasvibiswa yakapwanyika zvinhu zvinoda kunyatsocheneswa pamberi pegranulation.

Zvishoma Zvakakodzera Kusanganiswa Plastics: Material consistency inokanganisa pellet quality; mhando dzepolymer dzakasanganiswa dzinogona kuda kusanganisa kana kupatsanurwa.

Applications

Rigid Plastic Recycling: Yemabhodhoro eHDPE/PP, midziyo yeshampoo, madhiramu ekugezesa, nezvimwe.

Post-Industrial Plastic Scrap: Inokodzera zvakapwanyika zvakasara kubva mujekiseni rekugadzira, extrusion, kana kuvhuvhuta.

Yakashambwa Flakes kubva kuRecycling Lines: Inoshanda zvakanaka neyakacheneswa PET, PE, kana PP flakes kubva kumabhodhoro ekugeza masisitimu.

Plastic Pellet Vagadziri: Yakanakira vagadziri vanoshandura yakachena regrind kuita reusable pellets yejekiseni kana extrusion.

3. Yakarukwa bhegi bhegi recycling pelletizing mutsetse

A Woven Fabric Bag Recycling Pelletizing Line inyanzvi yekudzokorodza sisitimu yakagadzirirwa kugadzirisa PP (polypropylene) mabhegi akarukwa, raffia, jumbo mabhegi (FIBCs), uye mamwe akafanana machira epurasitiki. Izvi zvinhu zvinowanzoreruka, zvinodzivirira kubvarura, uye zvakaoma kudyisa zvakananga mumasikirwo echinyakare pelletizing nekuda kwehukuru hwazvo. Mutsetse uyu unosanganisa kupwanya, kubatanidza, extrusion, kusefa, uye pelletizing kuita inoenderera mberi inoshandura yakarukwa epurasitiki zvinhu kuita mayunifomu epurasitiki pellets.

Mhinduro iyi yakanakira kudzokorodza marara epashure-maindasitiri uye mushure mevatengi akarukwa, zvichibatsira kudzikisa kusvibiswa kwezvakatipoteredza uye kugadzira patsva zviwanikwa zveindasitiri yepurasitiki.

Zvakanakira

Yakabatanidzwa Compactor System: Inonyatso kumanikidza zvireruke, zvakarukwa zvinhu kuti ive nechokwadi chekudya chakatsiga uye chakatsiga mukati me extruder.

Kubudirira Kwepamusoro: Yakagadzirirwa kukwirira-kugona kugadzirisa nekuenderera mberi kwekushanda uye yakaderera manpower zvinodiwa.

Yakasimba uye Yakatsiga Kubuda: Inogadzira mayunifomu pellets ane yakanaka mechanic properties, akakodzera kushandiswa zvakare pasi perwizi.

Inobata Zvishandiso Zvinonetsa: Yakagadzirirwa chaizvo kubata mabhegi akarukwa, mabhegi ejumbo ane liner, uye marara eraffia.

Customizable Dhizaini: Inogadziriswa neakasiyana ekucheka, degassing, uye kusefa masisitimu akarongedzerwa kune akasiyana zvinhu.

Zvakaipa

Kugara Kunorapwa Kunodiwa: Mabhegi akarukwa anetsvina angangoda kugezwa nekuwomeswa asati adzokororwa kuitira kuchengetedza kunaka kwepellet.

Kushandiswa Kwemagetsi Akakwira: Nekuda kwekubatana uye kunyungudika kwezvinhu zvakakora, sisitimu inogona kushandisa simba rakawanda.

Material Sensitivity: Kusaenderana ukobvu hwezvinhu kana shinda dzekusona dzakasara zvinogona kukanganisa kudyisa uye extrusion kugadzikana.

Applications

Kudzokorodza PP Yakarukwa Masaga: Yakanakira masaga esimende, masaga emupunga, masaga eshuga, uye masaga ezvekudya kwemhuka.

Jumbo Bag (FIBC) Reprocessing: Mhinduro Inoshanda yekudzokorodza midziyo mikuru inochinjika yepakati yakawanda.

Textile uye Raffia Waste Recycling: Inokodzera vagadziri vemicheka yakarukwa uye zvigadzirwa zveraffia kuti vadzokorore edge trim uye zvimedu.

Plastic Pellet Production: Inogadzira yepamusoro-mhando PP granules kuti ishandiswezve mukuumba jekiseni, extrusion, kana kuridza firimu.

4.EPS/XPS Granulation Line

Iyo EPS/XPS Granulation Line inyanzvi yekudzokorodza sisitimu yakagadzirirwa kugadzirisa yakawedzera polystyrene (EPS) uye yakawedzera polystyrene (XPS) furo tsvina mumapurasitiki anogona kushandiswazve. EPS neXPS zvinhu zvisingaremi, zvine furo zvinowanzoshandiswa pakurongedza, kuvharisa, uye kuvaka. Nekuda kwekuwanda kwavo uye kuderera kwehuremu, vanonetsa kubata vachishandisa yakajairwa mapurasitiki ekudzoreredza midziyo. Iyi granulation line inowanzo sanganisira kupwanya, compacting (kunyungudika kana densifying), extrusion, filtration, uye pelletizing systems.

Chinangwa chikuru chemutsara uyu ndechekuderedza vhoriyamu, kunyunguduka, uye kudzokorora EPS/XPS furo tsvina kuita yunifomu polystyrene pellets (GPPS kana HIPS), iyo inogona kushandiswa zvakare mukugadzirwa kwepurasitiki.

Zvakanakira

Kuderedza Vhoriyamu: Iyo compactor kana densifier system inoderedza zvakanyanya kuwanda kwezvinhu zvefuro, kuvandudza kugona kwekudya.

Yakakwira Kubuda NeChiedza Zvishandiso: Yakagadzirirwa yakaderera-density furo, kuve nechokwadi chekudyisa kwakagadzikana uye kuenderera mberi kwekuwedzera.

Energy-Saving Screw Dhizaini: Yakagadziridzwa screw uye dhiramu chimiro chinogonesa kunyungudika nekudzikira simba rekushandisa.

Hushamwari Nezvakatipoteredza: Inobatsira kuderedza marara emarara uye inotsigira kushandiswa kwedenderedzwa kwefuro kurongedza uye zvinhu zvekudzivirira.

Recyclable Output: Iwo magranules anogadzirwa akakodzera kushandiswazve mune zvisiri zvechikafu maapplication semashizha ekudzivirira kana mapepa epurasitiki.

Zvakaipa

Inoda Kuchena uye Kuoma Foam: EPS / XPS inofanira kunge isina mafuta, chikafu, kana kusvibiswa kunorema kuchengetedza pellet mhando.

Kunhuwa uye Kudzora Utsi Zvinodiwa: Furo rinonyunguduka rinogona kuburitsa utsi; kufefetedza kwakakodzera kana kuti exhaust systems kwakakosha.

Haikodzeri Yakasanganiswa Plastics: Iyo sisitimu yakagadziridzwa kune yakachena EPS / XPS; zvinhu zvakasanganiswa zvinogona kuvhara kana kukanganisa kunaka kwekubuda.

Applications

Packaging Foam Recycling: Yakanakira kudzokorodza chena EPS yekurongedza inoshandiswa mumagetsi, midziyo, uye fenicha.

Kudzoreredza Material Kudzoreredza: Inokodzera XPS bhodhi zvimedu kubva pakuvaka insulation uye mapaneru emadziro.

Foam Factory Waste Management: Inoshandiswa neEPS/XPS vagadziri vezvigadzirwa kudzoreredza kugadzirwa kumucheto trim uye zvidimbu zvakarambwa.

Polystyrene Pellet Production: Inoshandura marara efuro kuita GPPS/HIPS magranules ekushandisa pasi pemvura semapepa epurasitiki, hangers, kana zvigadzirwa zvakaumbwa.

5. Parallel Twin Screw Granulation Line

A Parallel Twin Screw Granulation Line ipurasitiki yekugadzirisa sisitimu inoshandisa maviri akafanana intermeshing screws kunyungudusa, kusanganisa, uye pelletize akasiyana epurasitiki zvinhu. Kuenzaniswa ne single screw extruders, mapatya screws anopa zvirinani kusanganisa, kukwira kwepamusoro, uye kutonga kukuru pamusoro pemamiriro ekugadzirisa. Iyi sisitimu yakanyatsokodzera kudzokorodza mapurasitiki akavhenganiswa, kusanganisa zvinowedzera, uye kugadzira emhando yepamusoro magranules epurasitiki ane zvivakwa zvakavandudzwa.

Mutsara uyu unowanzo sanganisira yekudyisa system, parallel twin screw extruder, filtration unit, pelletizer, uye inotonhorera/kuomesa chikamu, chakagadzirirwa kuenderera uye kugadzikana kushanda.

Zvakanakira

Superior Kusanganisa uye Compounding: Twin screws inopa yakanakisa homogenization, inobvumira kusanganiswa kwemapolymer akasiyana uye ekuwedzera.

Yakakwira Kuburikidza uye Kubudirira: Inopa yakakwira kuburitsa uye zvirinani kugadzirisa kugadzikana kana ichienzaniswa neyeimwe screw extruders.

Versatile Material Handling: Inokodzera kugadzirisa akawanda epurasitiki, anosanganisira PVC, PE, PP, ABS, uye akadzokorodzwa akasanganiswa mapurasitiki.

Enhanced Process Control: Yakazvimirira screw yekumhanyisa uye tembiricha nzvimbo inobvumira kurongeka kwakaringana kwemhando yepamusoro pellet.

Kuvandudzwa kweDegassing: Kunyatsobvisa hunyoro uye kuparara, zvichiita kuti pave nekuchenesa pellets.

Zvakaipa

Yakakwira Yekutanga Investment: Twin screw masisitimu anowanzo kudhura kutenga nekuchengetedza pane imwechete screw extruder.

Kushanda Kwakaoma uye Kugadzirisa: Inoda vashandi vane hunyanzvi uye kugadzirisa nguva dzose kuchengetedza screws nemadhiramu ari mumamiriro akanaka.

Haina Yakanakira Yakanyanya-Yakanyanya-Viscosity Zvishandiso: Zvimwe zvakanyanya viscous zvinhu zvingada hunyanzvi michina kana mamiriro ekugadzirisa.

Applications

Plastic Recycling: Inoshanda pakugadzirisazve tsvina yepurasitiki yakasanganiswa kuita mayunifomu magranules kuti ashandiswezve.

Compounding uye Masterbatch Production: Inoshandiswa zvakanyanya mukugadzira epurasitiki makomisheni ane mafirita, colorants, kana additives.

PVC uye Engineering Plastics Processing: Yakanakira kubata kupisa-sensitive uye yakaoma ma polymers.

Yepamusoro-Kuita Material Manufacturing: Inoshandiswa mukugadzira mapurasitiki akasarudzika ane akarongedzerwa mechanical kana kemikari zvivakwa.

Pfungwa Dzakakosha Pakusarudza Zvakanakisisa Plastic Recycling Granulation Machine Type

Izvi zvinotevera zvimwe zvakakosha zvePlastiki Recycling Granulation Machine sarudzo inogona kuzadzisa zvaunoda kugadzira.

1. Ziva Rudzi Rwako

Mapurasitiki Akapfava (semuenzaniso, firimu, mabhegi, furo): Sarudza muchina une compactor kana densifier kuti uve nechokwadi chekudyisa.

Mapurasitiki akaoma (semuenzaniso, mabhodhoro, midziyo yakaoma): Mutsetse wakapwanyika wegranulation une kudya kwakagadzikana unonyanya kukodzera.

Yakasanganiswa kana Yakasvibiswa Plastics: Funga mapatya screw extruder ane yakasimba musanganiswa uye kusefa.

2. Ongorora Output Capacity Inodiwa

Fungidzira huwandu hwako hwemazuva ese kana hwemwedzi wega wega.

Sarudza modhi inoenderana nezvaurikuda throughput (kg/h kana matani/zuva) kudzivirira pasi- kana kudarika-saizi.

Pakudzokorodza kwakakura, yakakwira-inobuda twin-screw kana maviri-nhanho masisitimu akanakira.

3. Tarisa kune Kudyisa & Pre-kurapa Zvinodiwa

Zvinhu zvako zvinoda kugezwa, kuomeswa, kana kuti kupwanyiwa usati wagerwa here?

Mimwe michina inosanganisira yakasanganiswa shredders, washers, kana compactors. Zvimwe zvinoda midziyo yekunze.

Tsvina kana kunyorova zvinhu zvinoda yakasimba degas masisitimu uye kunyungudika kusefa.

4. Funga Final Pellet Quality

Zvekushandisa zvepamusoro-soro (semuenzaniso kuridza firimu, kuumbwa kwejekiseni), saizi yepellet inowirirana uye kuchena.

Michina ine chaiyo tembiricha yekudzora uye otomatiki skrini inochinja inoburitsa yakachena, yakawanda mayunifomu granules.

5. Kushanda Kwesimba & Automation

Tarisa michina ine inverter-inodzorwa mota, inochengetedza magetsi maheater, uye PLC otomatiki.

Otomatiki masisitimu anoderedza mutengo wevashandi uye anovimbisa kuenderana kwekugadzirwa kwemhando.

6. Maintenance & Spare Parts Support

Sarudza muchina kubva kumutengesi akavimbika ane kukurumidza-mhinduro sevhisi, tsigiro yehunyanzvi, uye nyore-kuwana maspare parts.

Madhizaini akareruka anogona kuderedza nguva yekudzikira uye kudzikisa-yenguva refu yekuchengetedza mari.

7. Customization & Ramangwana Kuwedzera

Funga michina ine modular dhizaini inobvumira kukwidziridzwa (semuenzaniso, kuwedzera yechipiri extruder kana kushandura pelletizing mhando).

Iyo inochinjika sisitimu inochinjika kune nyowani mhando dzemhando kana yepamusoro kuburitsa sezvo bhizinesi rako rinokura.

Funga nezveWUHE MACHINERY's Plastic Recycling Granulation Machine Service

Semugadziri ane hunyanzvi ane makore anopfuura makumi maviri echiitiko, WUHE MACHINERY (Zhangjiagang Wuhe Machinery Co., Ltd.) inokunda mukugadzira, kugadzira, uye sevhisi yepasirese yemapurasitiki ekudzoreredza granulation michina.

Neanopfuura 500 masisitimu akaiswa uye anopfuura 1 miriyoni matani epurasitiki akagadziriswa gore negore-kuderedza inofungidzirwa 360,000 matani eCO₂ emissions-WUHE yakaratidza kugona kwayo kwehunyanzvi uye kukanganisa kwezvakatipoteredza.

Inotsigirwa neISO 9001 uye CE certification, vanopa mhinduro dzakabatanidzwa dzefirimu, bhegi rakarukwa, EPS/XPS, mapurasitiki akapwanyika, uye mapatya-screw granulation mitsara. Yavo yakasimba yemhando yekudzora, modular sisitimu dhizaini, OEM/ODM kuchinjika, uye inoteerera mushure mekutengesa-rutsigiro inovimbisa kuti vatengi veB2B vanowana yakavimbika, yepamusoro-soro, uye yakarongedzerwa kudzokorora mhinduro pasi rese.

Sarudza WUHE MACHINERY yekuita yakavimbika, yakagadziridzwa kugadzirisazve mhinduro, uye waanovimba naye mukuvaka girini, inogoneka mapurasitiki indasitiri.

Nguva yekutumira: Jul-01-2025